Mini Solenoid Valves are compact, electrically operated devices that are widely used in various fluid control applications. These valves are designed to regulate the flow of liquids or gases in systems where space is at a premium, or where precise control and quick response times are required. The miniaturization of solenoid valves has made them indispensable in many industries, from medical equipment to automotive systems. In this article, we will explore the advantages, working principles, and diverse applications of mini solenoid valves.

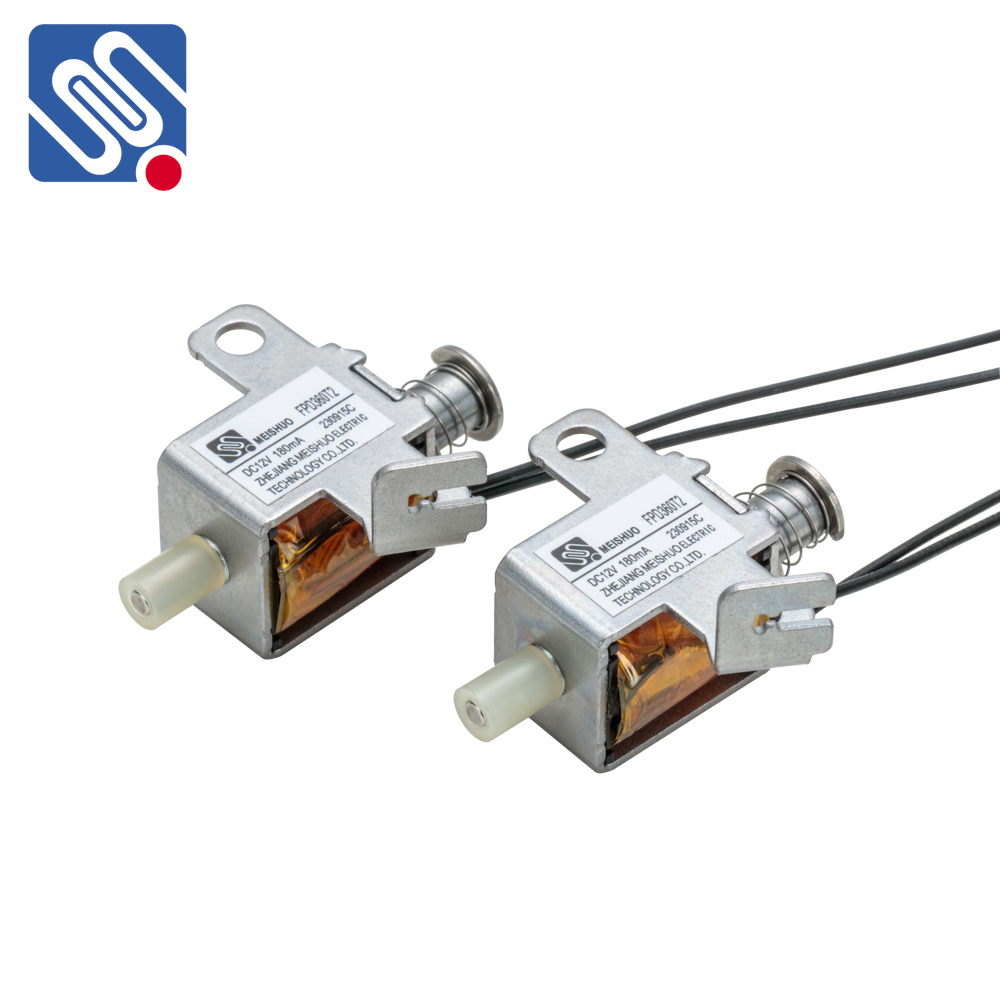

What is a Mini Solenoid Valve? A Mini Solenoid Valve is essentially a smaller version of a standard solenoid valve, designed to perform the same basic function: controlling the flow of a fluid (either gas or liquid) within a system. The key difference is in its size. Mini solenoid valves are typically designed for applications where space constraints or a need for low-power operation are present. Despite their small size, they provide high precision and reliable control, making them suitable for a wide range of industries. The valve consists of a solenoid coil, a movable armature, and a valve body. When an electric current passes through the solenoid coil, it generates a magnetic field that moves the armature, opening or closing the valve to regulate fluid flow. The valve can be either normally open (NO) or normally closed (NC), depending on the specific requirements of the system.