Explosion-proof electric butterfly valves are essential components in industries that deal with hazardous materials, ensuring both safety and efficiency in fluid and gas flow control. These valves are specifically designed to withstand explosive environments, providing a robust solution for applications in industries such as oil and gas, chemicals, pharmaceuticals, and mining. In this article, we will explore the functionality, importance, and benefits of explosion-proof electric butterfly valves, along with the factors to consider when selecting the right valve for specific applications.

What is an Explosion-Proof Electric Butterfly Valve?

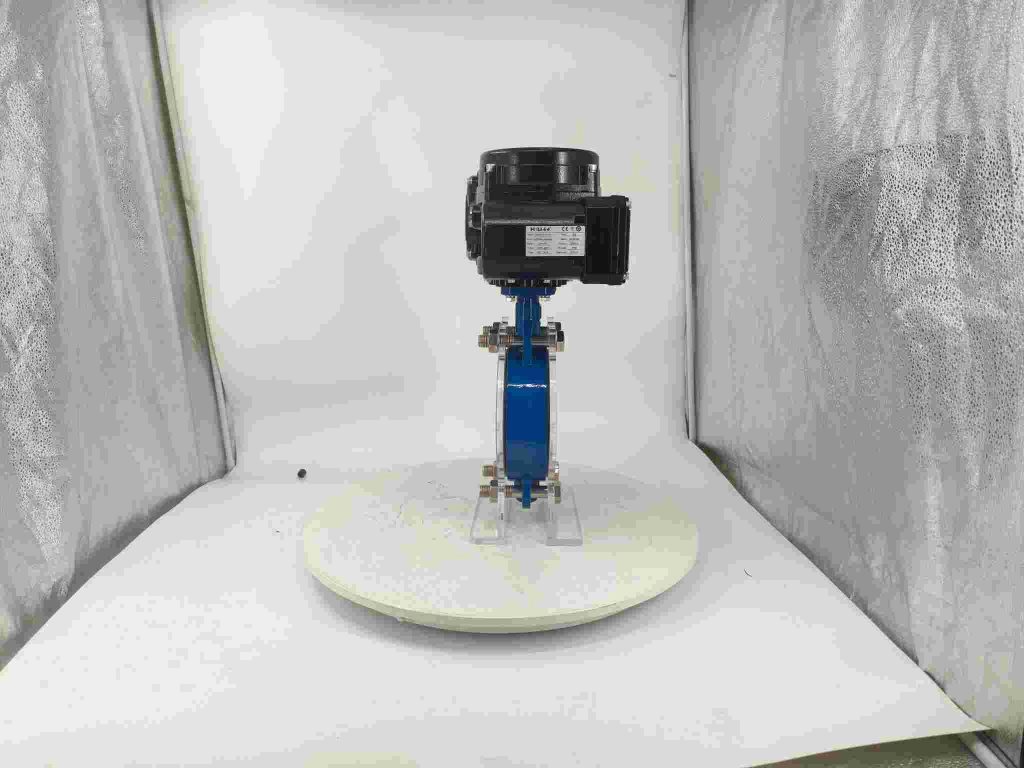

An explosion-proof electric butterfly valve is a type of quarter-turn valve that is powered by an electric actuator. These valves are designed with special enclosures and materials that can withstand extreme conditions, such as high temperatures and the presence of explosive gases or dust. The butterfly valve itself consists of a disc that rotates within the pipe to control the flow of liquids or gases. The electric actuator, which operates the valve remotely, offers precise control and automation, reducing the need for manual operation and enhancing efficiency. The “explosion-proof” designation refers to the valve’s ability to operate safely in potentially explosive environments without causing sparks or ignition. These valves are built to meet strict safety standards, ensuring that they do not compromise the integrity of the system, even under extreme conditions.