In today’s industrial landscape, safety and efficiency are paramount. One critical component that ensures both in various applications is the explosion-proof electric butterfly valve. As industries seek reliable solutions to manage the flow of fluids in potentially hazardous environments, the demand for high-quality valves has led to the emergence of specialized manufacturers. Among them, explosion-proof electric butterfly valve ODM (Original Design Manufacturer) manufacturers stand out as key players in delivering customized, safe, and efficient solutions tailored to meet the specific needs of various sectors.

Understanding Explosion-Proof Electric Butterfly Valves

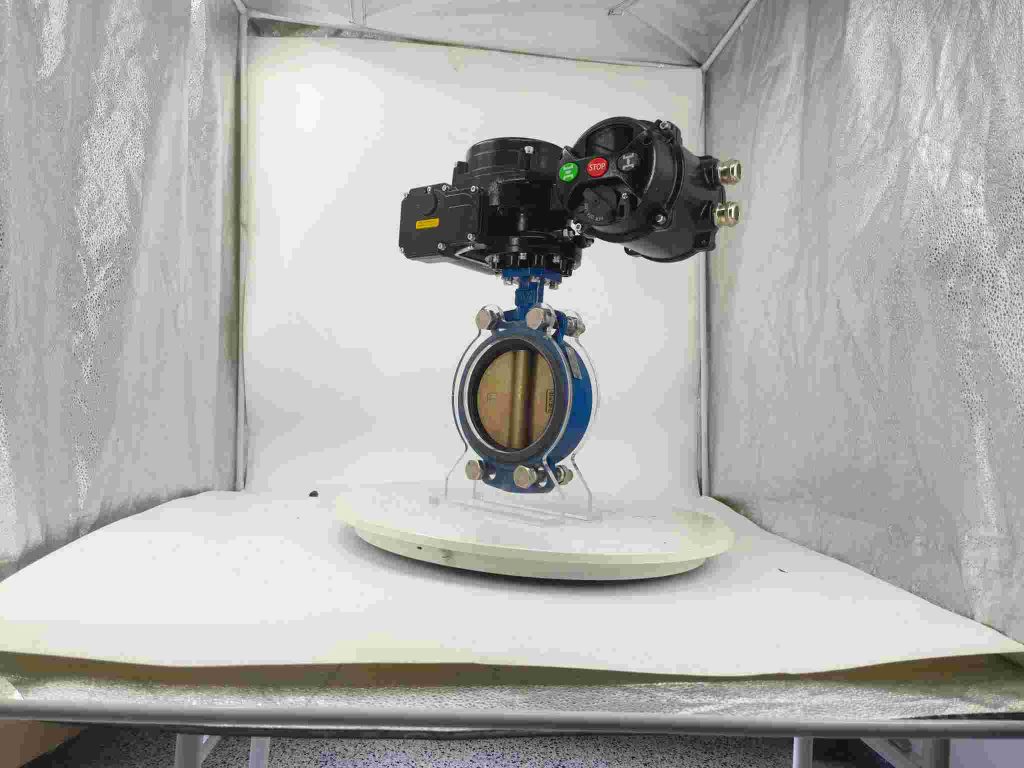

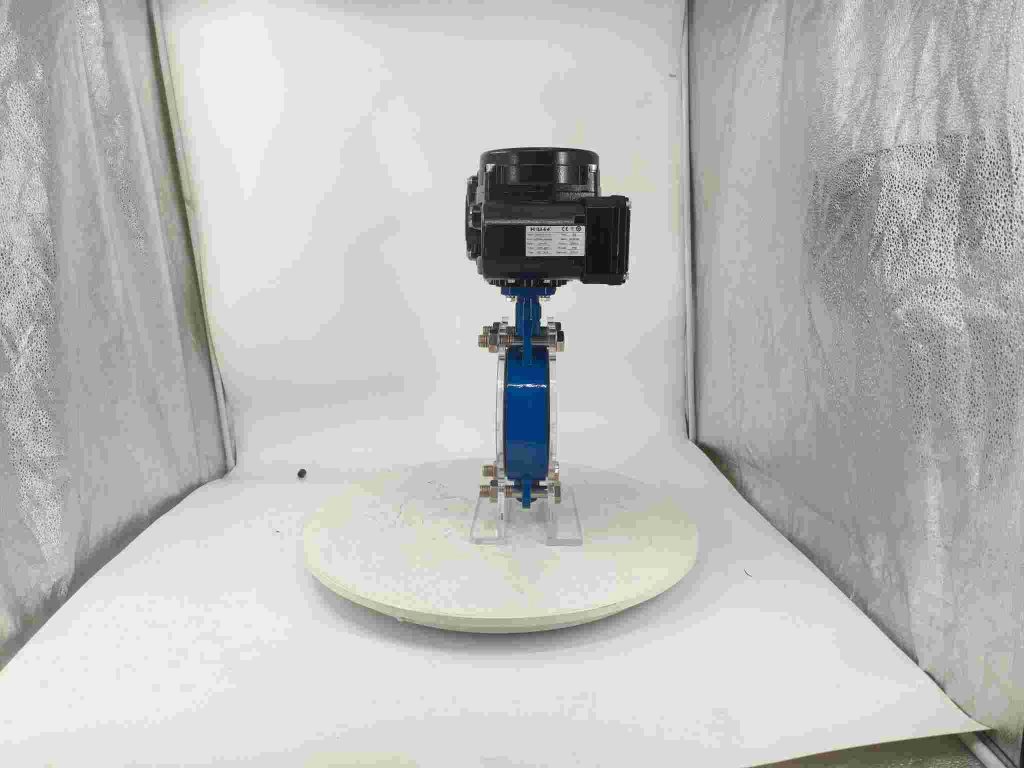

Explosion-proof electric butterfly valves are designed to control the flow of liquids and gases in environments where the risk of explosion is significant. These valves are constructed using robust materials that can withstand extreme conditions, ensuring they function effectively even in hazardous environments. The explosion-proof feature is achieved through meticulous design and engineering, which includes protective measures like explosion-proof enclosures and flame paths that prevent ignition of flammable gases or dust. Butterfly valves, known for their compact design and quick operation, consist of a disc that pivots on a shaft to open or close the flow path. Electric actuators enable remote or automatic control, making them ideal for modern industrial automation systems. The combination of these features makes explosion-proof electric butterfly valves an essential choice for industries such as oil and gas, chemical processing, mining, and pharmaceuticals.

Leave a Reply