Mini solenoid valves are integral to a variety of fluid control systems due to their compact size, high efficiency, and reliable performance. These valves are designed to control the flow of liquids or gases in systems where space is limited, making them highly desirable for applications in fields such as automation, medical devices, and HVAC systems. In this article, we will explore the key features, applications, and benefits of mini solenoid valves, as well as discuss how they contribute to the overall performance of fluid control systems.

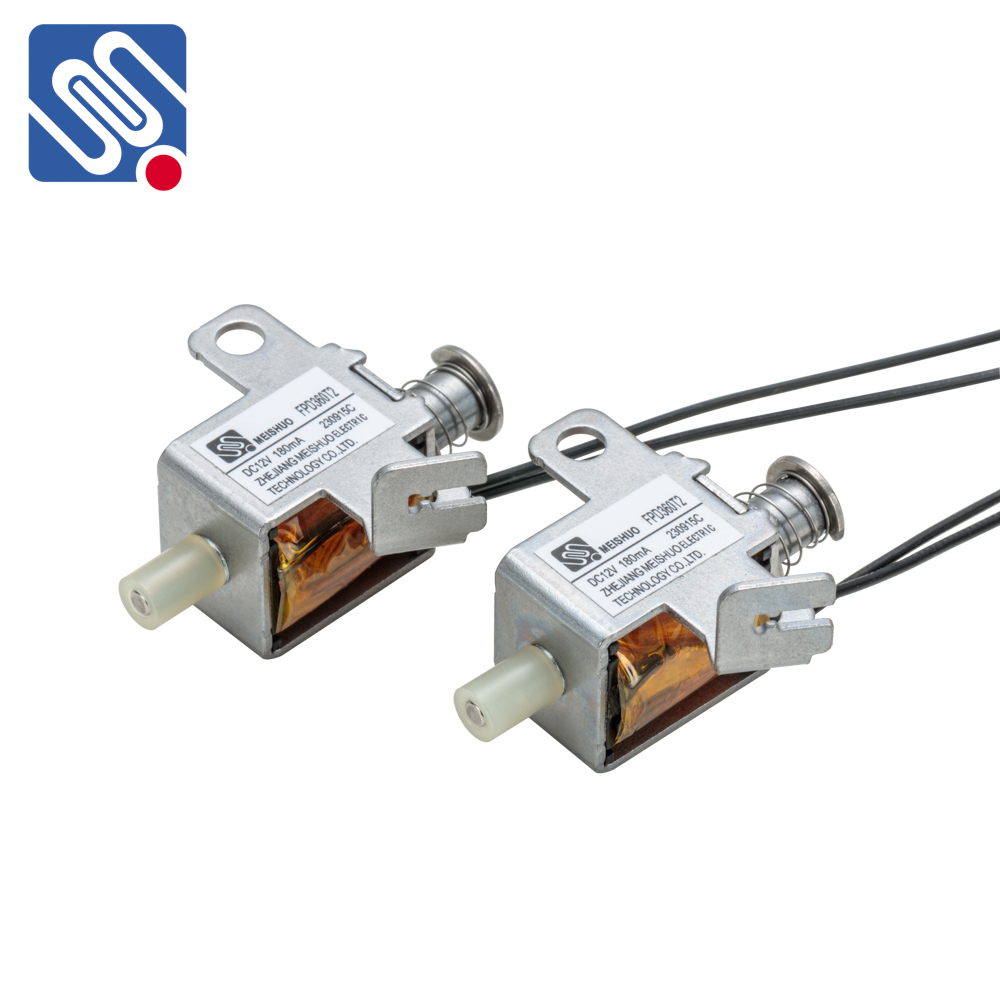

What is a Mini Solenoid Valve? A solenoid valve is an electromechanical device used to control the flow of fluids in a system. It operates by using an electric current to generate a magnetic field that moves a plunger or armature, opening or closing the valve. The “mini” version of the solenoid valve refers to smaller-sized valves designed for use in systems where space constraints are a factor. These valves typically offer the same functionality as larger solenoid valves but in a more compact form. Mini solenoid valves are usually designed to be used with gases or liquids in low to medium-pressure applications. They can be either normally open (NO), meaning the valve is open when the coil is not energized, or normally closed (NC), meaning the valve is closed when the coil is not energized. These valves are commonly used in systems that require quick and precise fluid control, often with very little physical space to spare.

Leave a Reply

You must be logged in to post a comment.