Industrial relays are vital components in modern automation systems and electrical circuits. These electromechanical or solid-state devices are used to control high-power devices through low-power signals. Their ability to switch large currents or voltages using minimal power makes them indispensable in industrial applications ranging from machinery control to electrical safety. This article delves into the functionality, types, and applications of industrial relays, helping to explain their significance in a wide variety of industries.

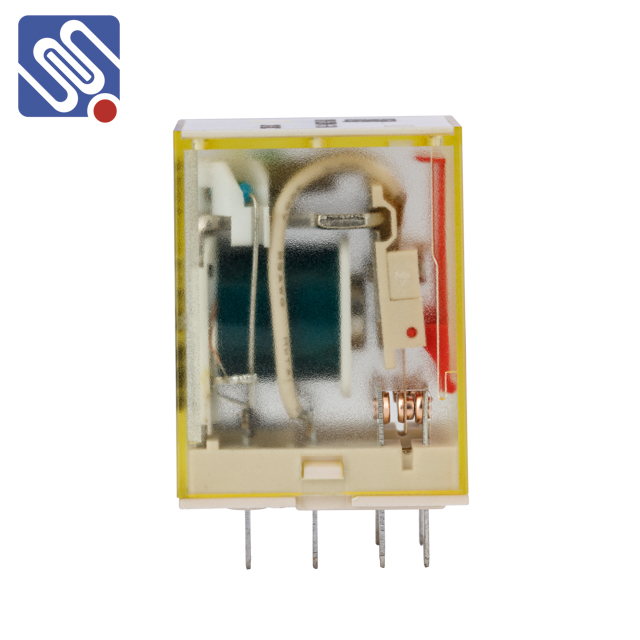

Key Components of an Industrial Relay At its core, an industrial relay is made up of several key components that work together to facilitate switching operations: Coil: The coil is an electromagnet that, when energized with current, generates a magnetic field. This magnetic field is what triggers the relay to perform its switching action. Contacts: These are the points where the electrical current flows through to the load (such as motors or lights). The contacts can either open or close, depending on the relay’s operation. Armature: The armature is the movable component that is attracted to the coil when the magnetic field is created. This movement either opens or closes the contacts.