China has long been a hub for industrial manufacturing, and its dominance extends to the production of critical components for various industries. Among these components, PVC (Polyvinyl Chloride) solenoid valves stand out as an essential part of fluid control systems used in numerous sectors, including chemical processing, water treatment, food and beverage, and HVAC systems. PVC solenoid valves are known for their durability, corrosion resistance, and cost-effectiveness, making them a popular choice for controlling fluid flow in a range of applications.

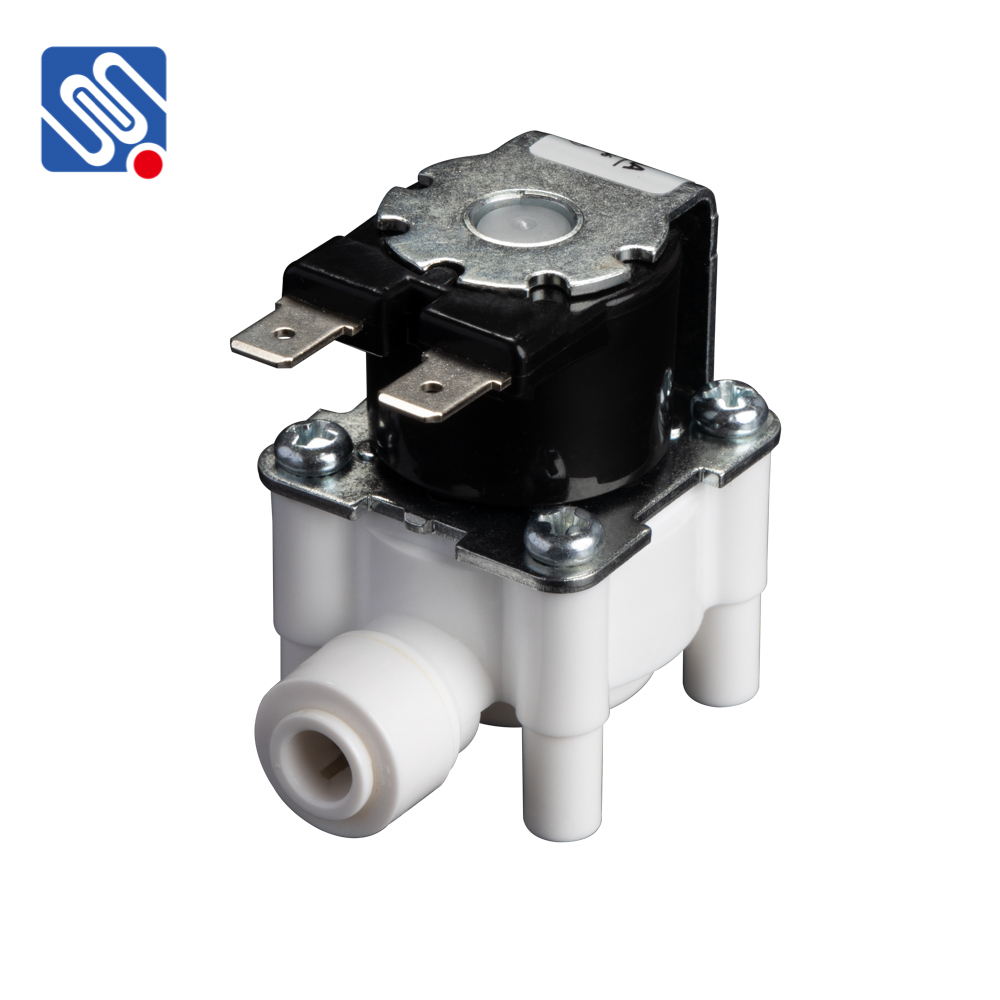

The Role of PVC Solenoid Valves in Modern Industries Solenoid valves are electromechanical devices used to control the flow of liquids and gases in a system. These valves operate using an electric current to control a solenoid, which then moves the valve to either open or close it. PVC solenoid valves, specifically, are favored for their resistance to corrosive materials, making them ideal for industries dealing with harsh chemicals or liquids that would otherwise corrode metal valves. One of the primary reasons for the widespread adoption of PVC solenoid valves is their material properties. PVC is lightweight, resistant to corrosion, and relatively inexpensive compared to metals, making it an ideal choice for a wide range of applications. These valves can be used in water treatment plants, where they regulate the flow of water or chemicals, and in the chemical industry, where their resistance to acids, alkalis, and other corrosive substances is crucial.