The Durable Plastic Solenoid Valve is an essential component in modern fluid control systems, offering both precision and durability for a wide range of applications. Comprising mainly plastic materials like PVC, PP, and PVDF, these valves are designed to withstand harsh conditions while providing efficient and reliable control of liquid or gas flow. In industries where corrosion resistance, cost-effectiveness, and longevity are paramount, durable plastic solenoid valves have proven to be a preferred solution. This article explores the features, benefits, applications, and potential limitations of durable plastic solenoid valves.

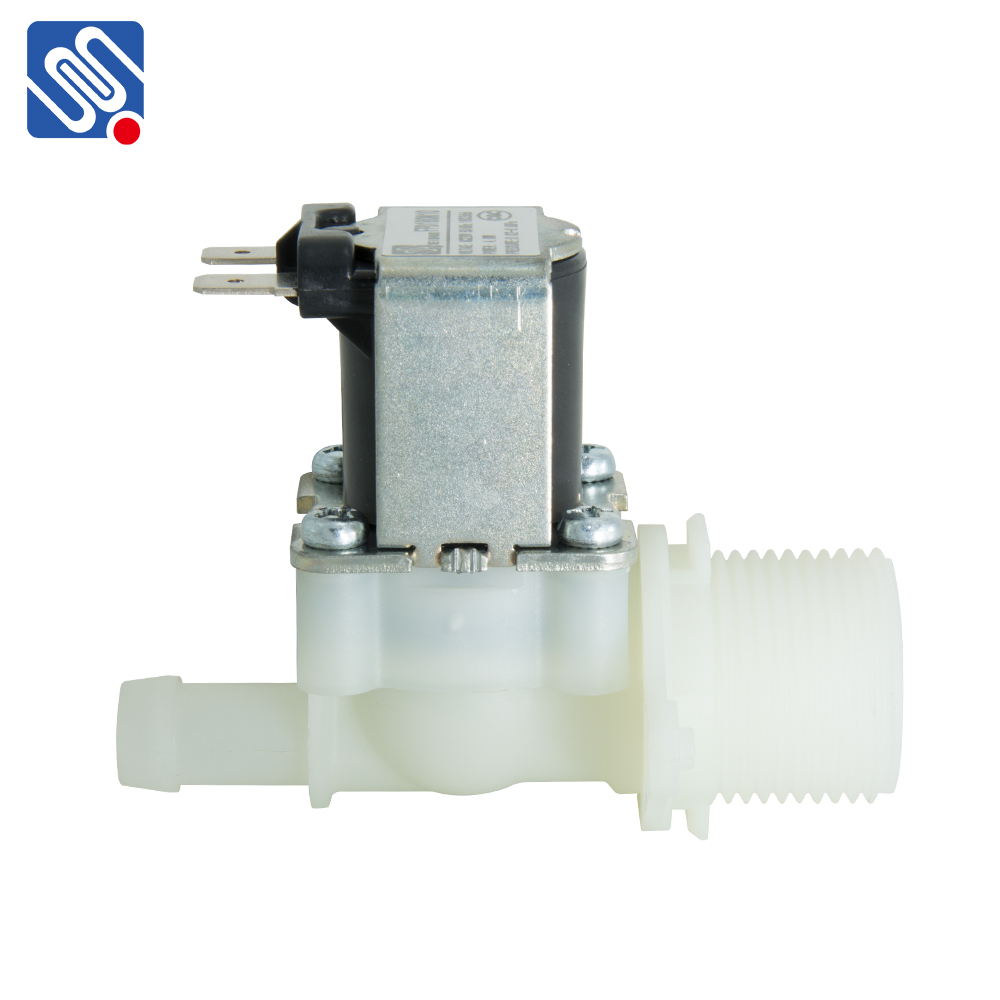

What is a Durable Plastic Solenoid Valve? A solenoid valve is an electromechanically operated valve that controls the flow of fluids (liquids or gases) by using an electric current to generate a magnetic field. The valve typically consists of a coil, a plunger, and a valve body. In a durable plastic solenoid valve, the valve body and other components are made of robust plastic materials that offer resistance to corrosion and chemical degradation. Unlike traditional solenoid valves made from metals like brass or stainless steel, plastic solenoid valves are favored for environments where exposure to aggressive chemicals, high acidity, or basic conditions is a concern. The combination of plastic’s corrosion resistance and the solenoid valve’s precise control mechanism makes them an ideal choice in applications demanding both durability and precision.