In the realm of industrial automation and process control, safety and reliability are paramount. One of the critical components designed to address these needs is the explosion-proof electric butterfly valve. For industries operating in hazardous environments, such as petrochemical, mining, and chemical processing sectors, these valves are essential for ensuring operational safety and efficiency. This article delves into the role and significance of Explosion-Proof Electric Butterfly Valve ODM (Original Design Manufacturer) manufacturers, exploring their contributions to industrial safety and operational excellence.

The Role of Explosion-Proof Electric Butterfly Valves

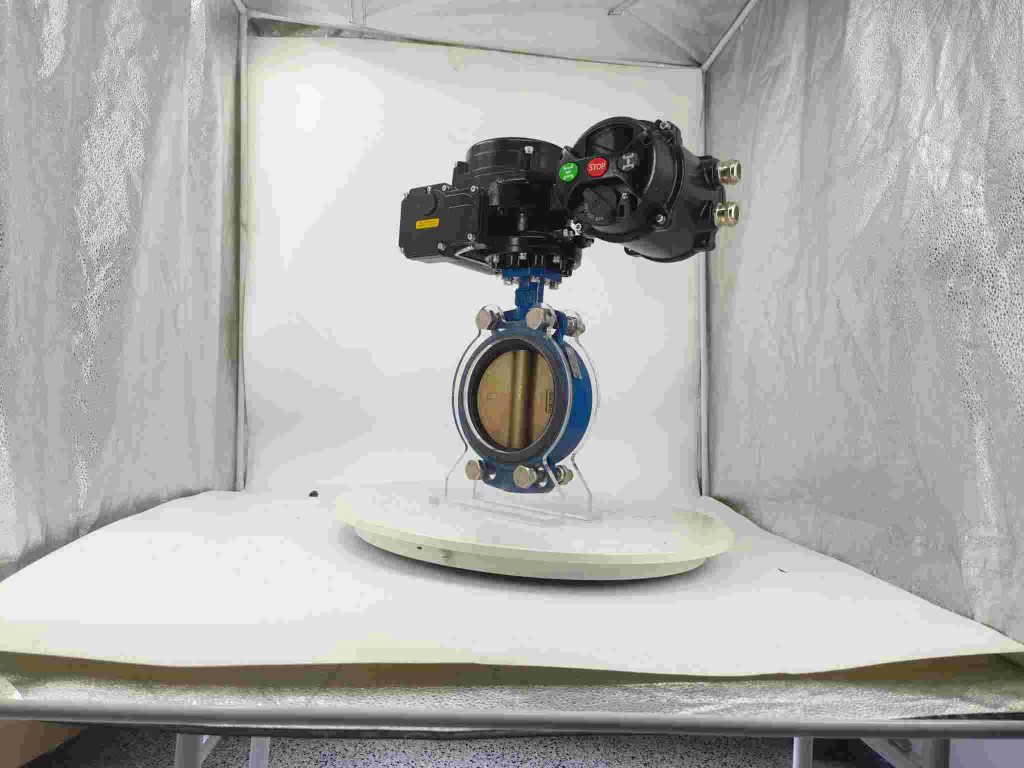

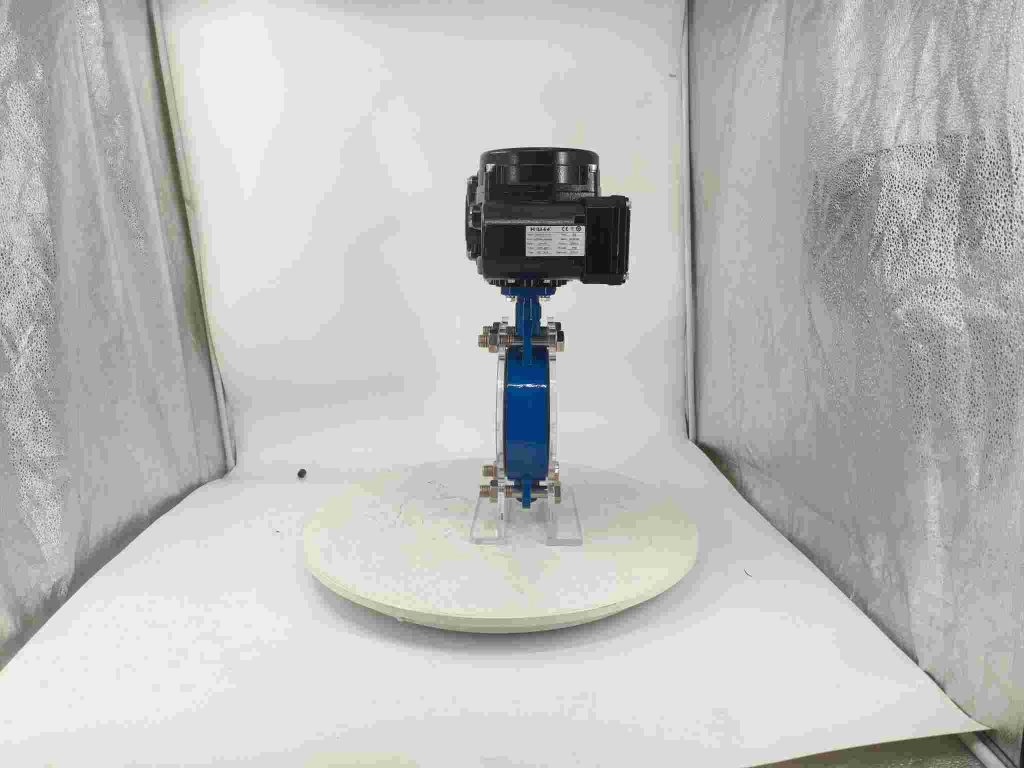

Explosion-proof electric butterfly valves are engineered to provide reliable shutoff and control of fluids in potentially explosive atmospheres. Their design incorporates robust features to prevent ignition and ensure safe operation. These valves are characterized by their ability to withstand high pressures and temperatures while maintaining airtight sealing. Key attributes of explosion-proof electric butterfly valves include: Explosion-Proof Design:These valves are built to prevent sparks or heat from igniting flammable substances in explosive environments. They comply with stringent international standards, such as ATEX (Atmosphères Explosibles) and IECEx (International Electrotechnical Commission Explosive), to ensure safe operation.

Leave a Reply