In today’s industrial landscape, safety and efficiency are paramount. Industries that operate in hazardous environments, such as oil and gas, chemical processing, and power generation, face unique challenges in ensuring the safety of their operations. One crucial piece of equipment designed to address these challenges is the explosion-proof electric butterfly valve. Among the companies leading the charge in developing and innovating solutions for such high-risk environments is Helite Automation, which has earned a reputation for producing reliable, durable, and cutting-edge automation equipment.

Understanding Explosion-Proof Electric Butterfly Valves

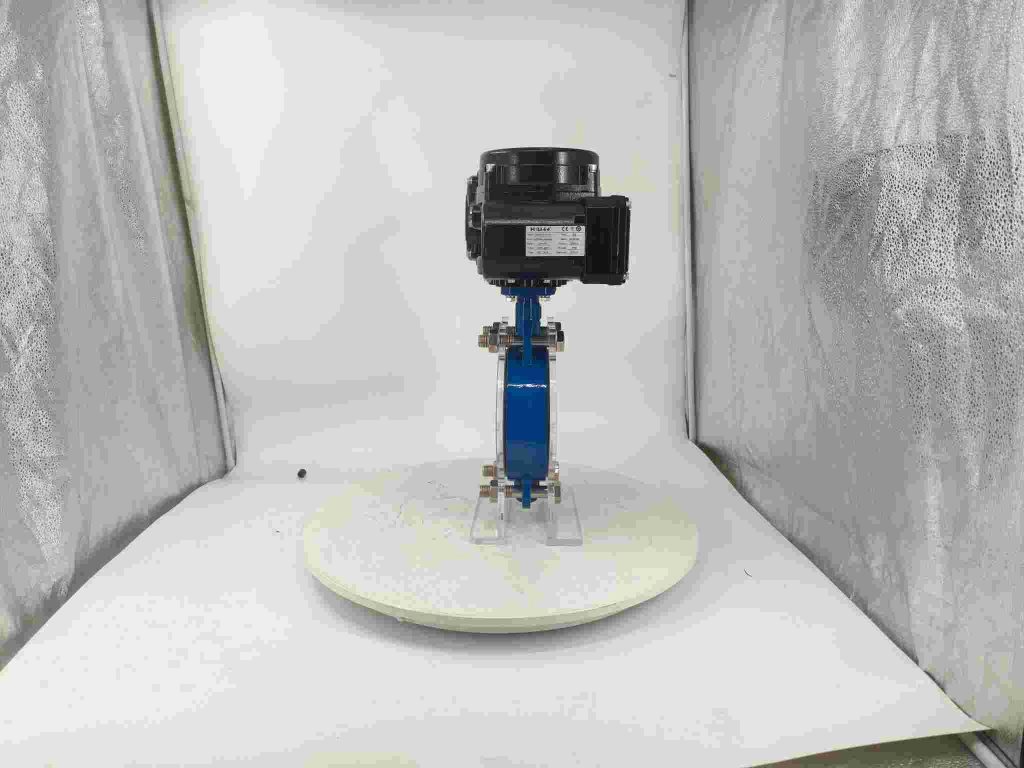

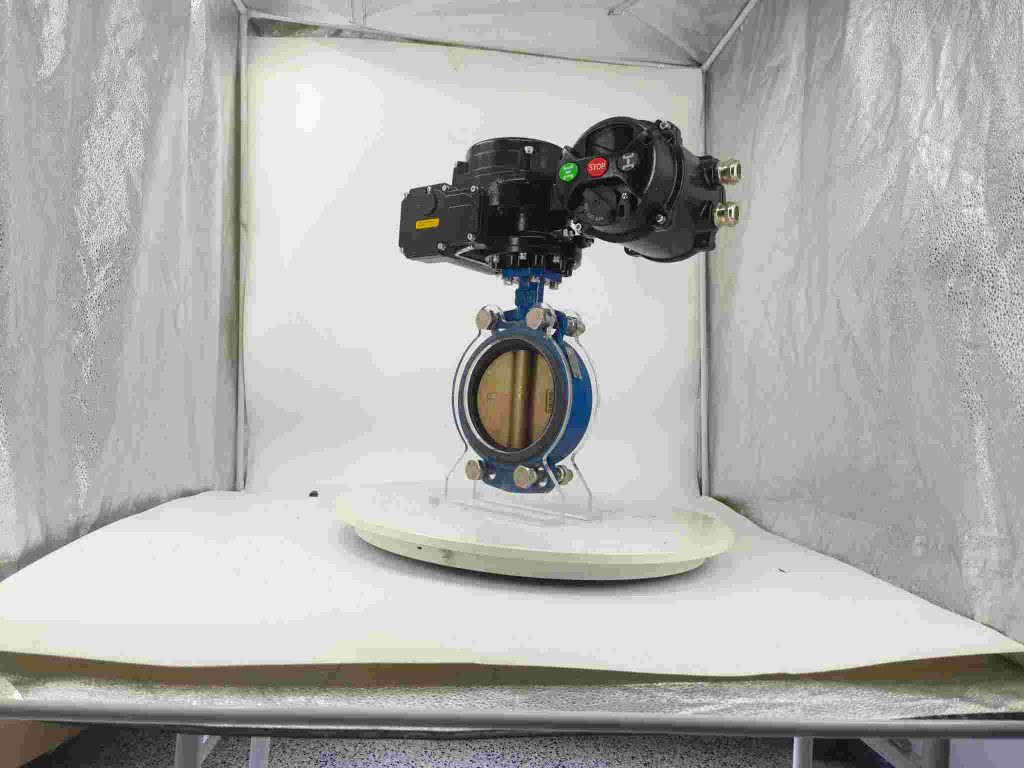

A butterfly valve is a type of flow control device used to regulate, isolate, or control the flow of a fluid or gas in a pipeline. It consists of a circular disc or “butterfly” that rotates on a spindle to either allow or block the flow. The primary benefit of a butterfly valve lies in its compact design, cost-effectiveness, and ease of operation. An explosion-proof electric butterfly valve is designed specifically to operate in environments where there is a risk of explosion due to the presence of flammable gases or vapors. These valves are equipped with electric actuators that provide precise control, often coupled with explosion-proof enclosures that protect the valve’s electrical components. The electric actuator can be remotely operated, making it highly suitable for systems requiring automation and advanced control.