In industries where explosive atmospheres are present, safety is of paramount importance. One crucial component used to ensure both operational efficiency and safety in such environments is the Explosion-proof electric butterfly valve. These valves are designed to control the flow of fluids and gases while minimizing the risk of ignition, which could lead to catastrophic consequences. In this article, we will explore the features, benefits, applications, and importance of explosion-proof electric butterfly valves, focusing on their critical role in maintaining safety and reliability in industrial settings.

What is an Explosion-proof Electric Butterfly Valve?

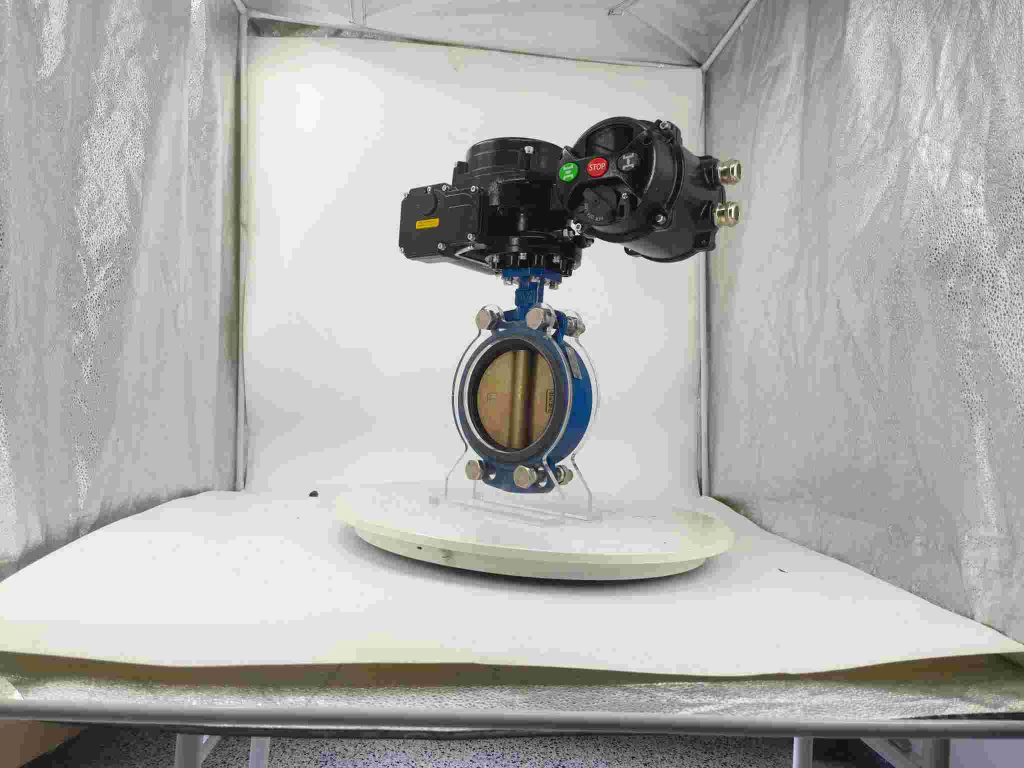

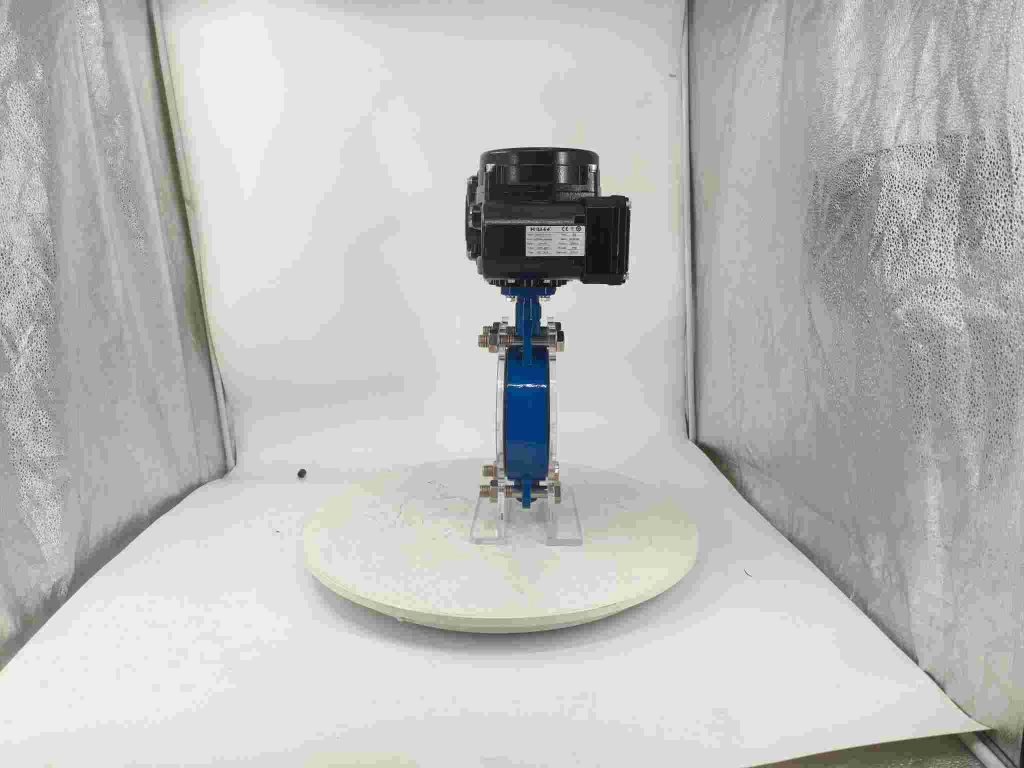

An explosion-proof electric butterfly valve is a type of valve that combines the functionality of a butterfly valve with an electric actuator. This specialized valve is designed for use in hazardous environments, such as those found in the oil and gas, chemical, pharmaceutical, and mining industries, where flammable gases or vapors may be present. The “explosion-proof” designation means that the valve is built to withstand and contain an internal explosion, preventing it from igniting the surrounding environment. The butterfly valve itself is a quarter-turn valve featuring a disc that rotates to control the flow of substances. When combined with an electric actuator, the valve can be operated remotely, which is particularly beneficial for controlling the flow in areas that may be difficult or dangerous for manual intervention.

Leave a Reply

You must be logged in to post a comment.