In today’s industrial world, where safety, reliability, and operational efficiency are paramount, equipment like valves play a crucial role in ensuring the smooth operation of various systems. Among the different types of valves, the explosion-proof electric butterfly valve stands out as a key component, especially in industries dealing with hazardous environments. Explosion-proof electric butterfly valves are essential for maintaining control over fluid and gas flow while preventing accidents in volatile settings. This article explores the importance of explosion-proof electric butterfly valves, the role of ODM (Original Design Manufacturer) manufacturers, and how they are shaping the future of industrial applications.

Understanding Explosion-proof Electric Butterfly Valves

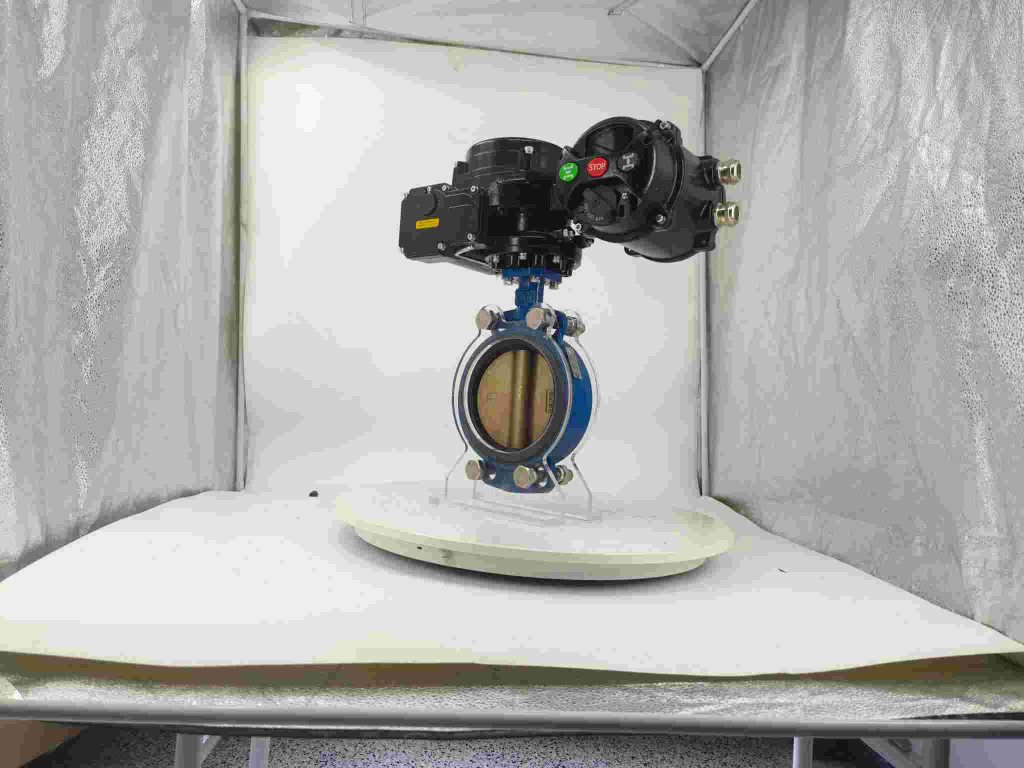

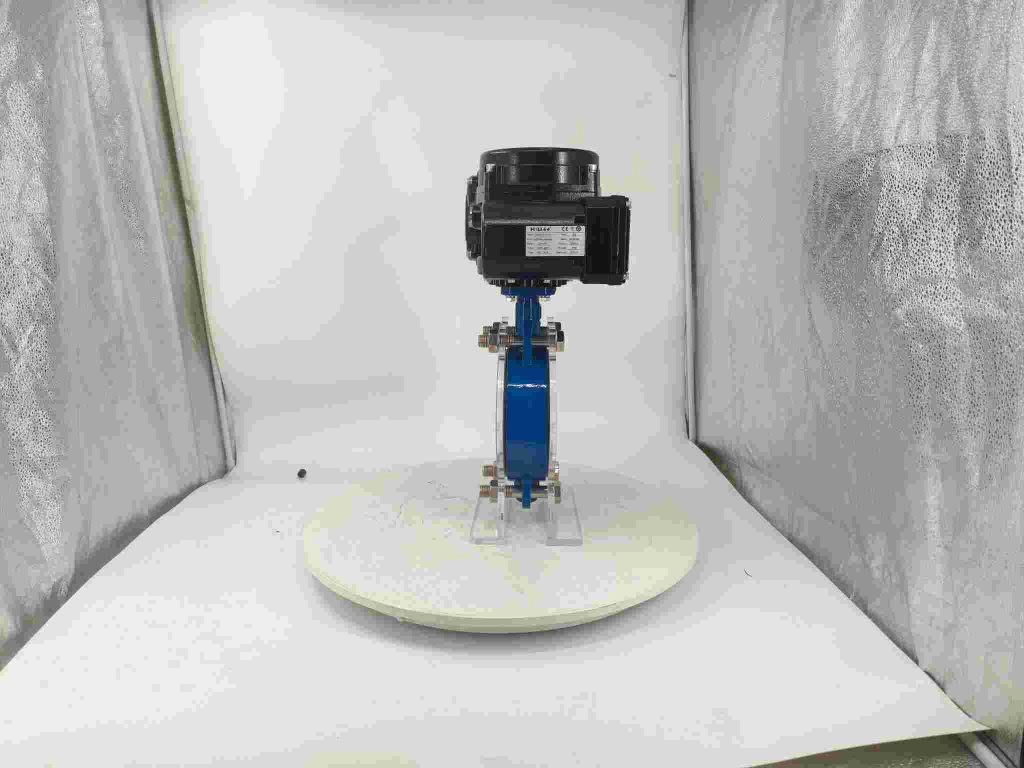

Explosion-proof electric butterfly valves are designed to regulate the flow of fluids or gases in environments where there is a risk of fire, explosion, or hazardous conditions. These valves are equipped with electric actuators, allowing for precise and automated control. The primary feature of explosion-proof butterfly valves is their robust construction, which is engineered to withstand extreme conditions. They are specifically designed to prevent any electrical sparks or heat from igniting flammable substances in the environment. The butterfly valve design itself is simple yet effective. The valve consists of a disc (or “butterfly”) that rotates within a pipe to regulate or shut off the flow. When combined with an electric actuator, the valve becomes highly efficient, offering rapid response times and the ability to control large volumes of flow with minimal effort.

Leave a Reply

You must be logged in to post a comment.