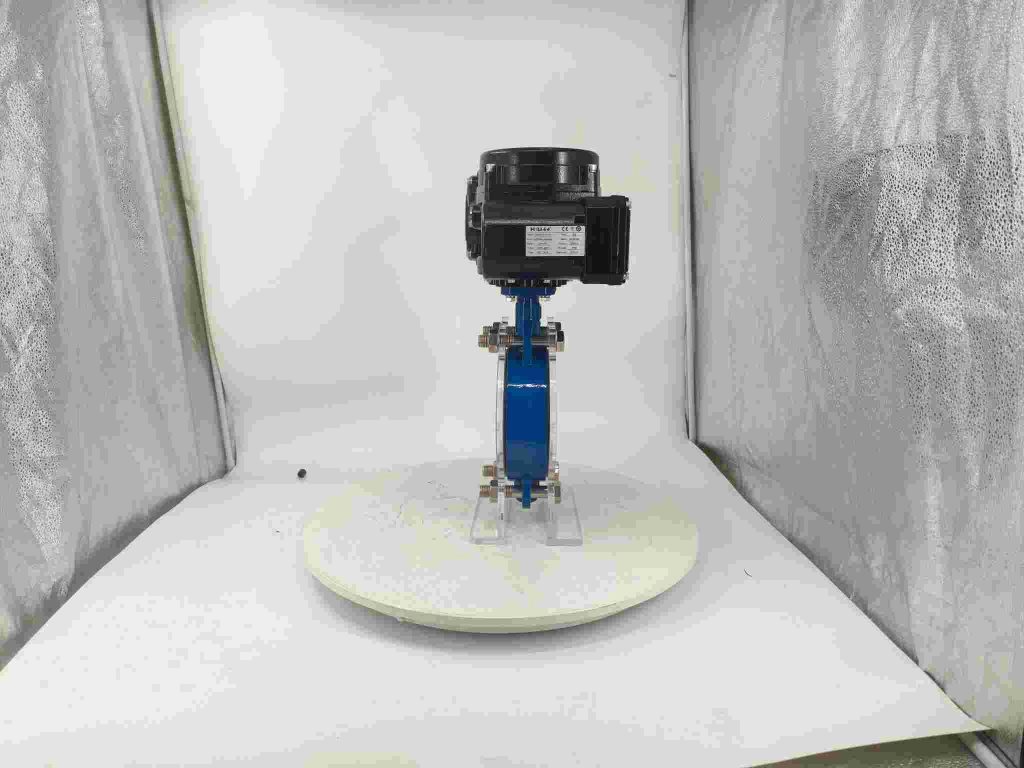

Explosion-proof electric butterfly valves are essential components in industries where safety and precision are paramount, especially in environments prone to hazardous explosions. These specialized valves combine the robust performance of a butterfly valve with an electric actuator, ensuring optimal fluid control and mitigating the risks associated with volatile gases, chemicals, and dust. This article explores the role of Explosion-proof electric butterfly valve OEM manufacturers in delivering reliable, safe, and efficient valve solutions to various industries.

The Role of Explosion-proof Electric Butterfly Valves

An explosion-proof electric butterfly valve is designed to regulate fluid or gas flow in environments that present potential explosion hazards. These environments often contain flammable gases or dust particles that, if ignited, could result in catastrophic accidents. The explosion-proof design of the valve ensures that it does not become a source of ignition, effectively protecting workers and equipment in hazardous areas. The butterfly valve itself is a quarter-turn valve, consisting of a disc that rotates around an axis to control the flow of fluids. It is often used in industries where space and weight are concerns due to its compact design. When coupled with