A one way solenoid valve is a vital component in various fluid control systems, ensuring that the flow of liquids or gases occurs in one direction only. By controlling the flow of fluids with precision, it plays an essential role in a wide range of industries, including automation, water treatment, HVAC, and automotive systems. This article will explore the structure, working principle, applications, and advantages of the one-way solenoid valve, highlighting its importance in modern fluid handling systems.

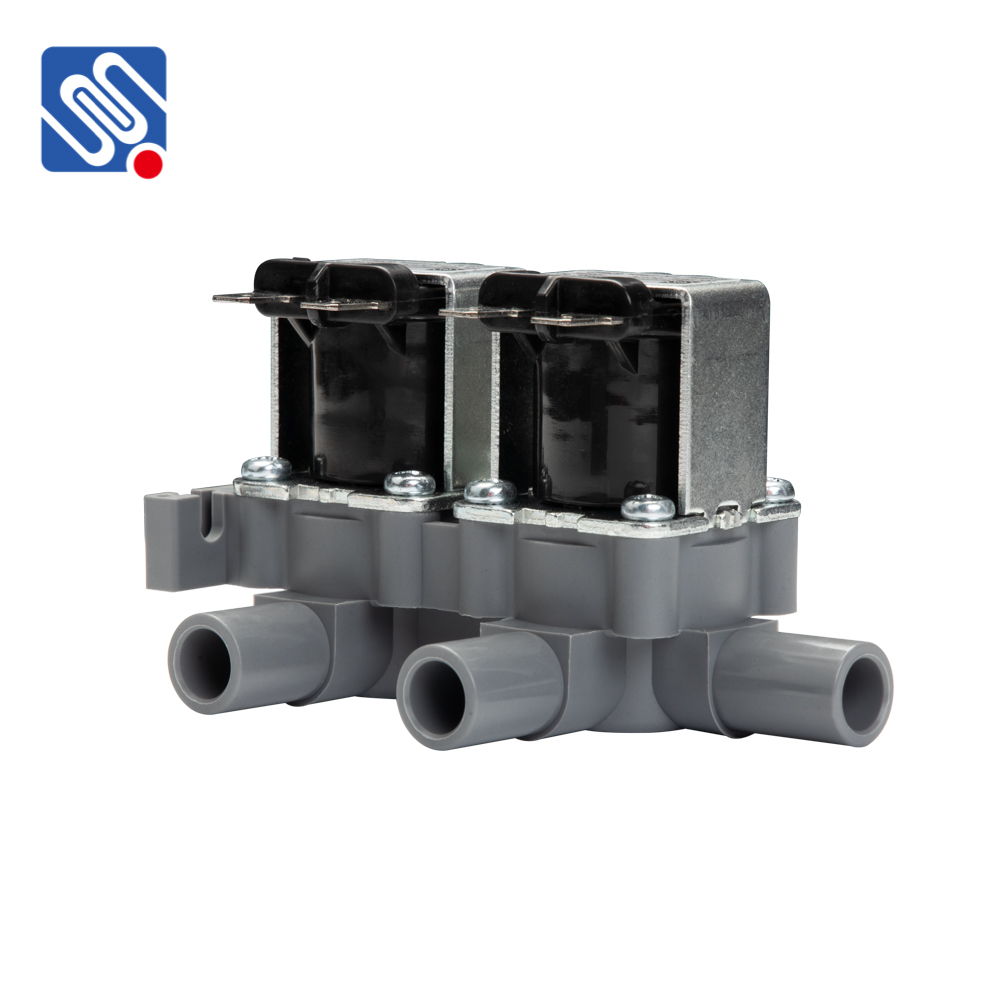

Structure of One Way Solenoid Valve A one-way solenoid valve typically consists of several key components: the solenoid coil, valve body, valve seat, valve core, and a spring. The solenoid coil is the electromagnetic part of the valve, and it is powered by an electrical signal. When the coil is energized, it creates a magnetic field that moves the valve core, allowing or blocking the flow of fluid through the valve. The valve seat is the part that seals the valve and directs the fluid, while the spring may be used to return the valve to its default position when power is turned off. The simplicity of its design makes it a highly reliable and effective tool for controlling fluid flow in both small and large systems. It operates without the need for manual intervention, making it ideal for automated systems that require high precision and efficiency.