When designing electronic systems, automation circuits, or control panels, selecting the right relay is crucial for ensuring the efficient operation of the system. A relay, as a switching device, controls the flow of electrical current in circuits. It is essential to consider several factors when selecting the appropriate relay type to match the requirements of your specific application. This article explores the various relay types, key considerations for selection, and how to make an informed choice based on load characteristics, environmental conditions, and application needs.

1. Understanding Relay Types Relays come in different types, each designed for specific applications. The two primary categories of relays are mechanical relays and solid-state relays (SSRs).

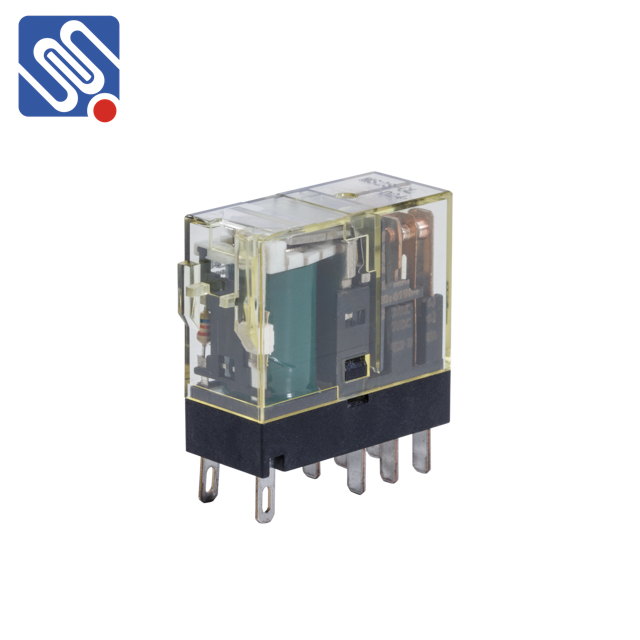

Mechanical Relays (Electromechanical Relays, EMRs): These are the traditional type of relay that use physical contact points to open or close the circuit. They consist of a coil and a set of mechanical contacts that are operated when current is passed through the coil. Mechanical relays are ideal for low-frequency switching and are often used in industrial control systems. Solid-State Relays (SSRs): These relays use semiconductor components instead of mechanical contacts to switch the circuit. They offer faster switching times and longer life cycles since there are no moving parts. Solid-state relays are suitable for high-frequency operations and environments that require precise control without the wear and tear of mechanical contacts.