The Explosion-proof electric butterfly valve is a critical component in industries where hazardous environments are a constant concern. Designed to provide effective control over fluid flow while ensuring safety, these valves are engineered to prevent explosions or fires in areas prone to volatile substances. This article explores the design, features, and common applications of explosion-proof electric butterfly valves, highlighting their importance in ensuring both operational efficiency and safety in dangerous environments.

What is an Explosion-proof Electric Butterfly Valve?

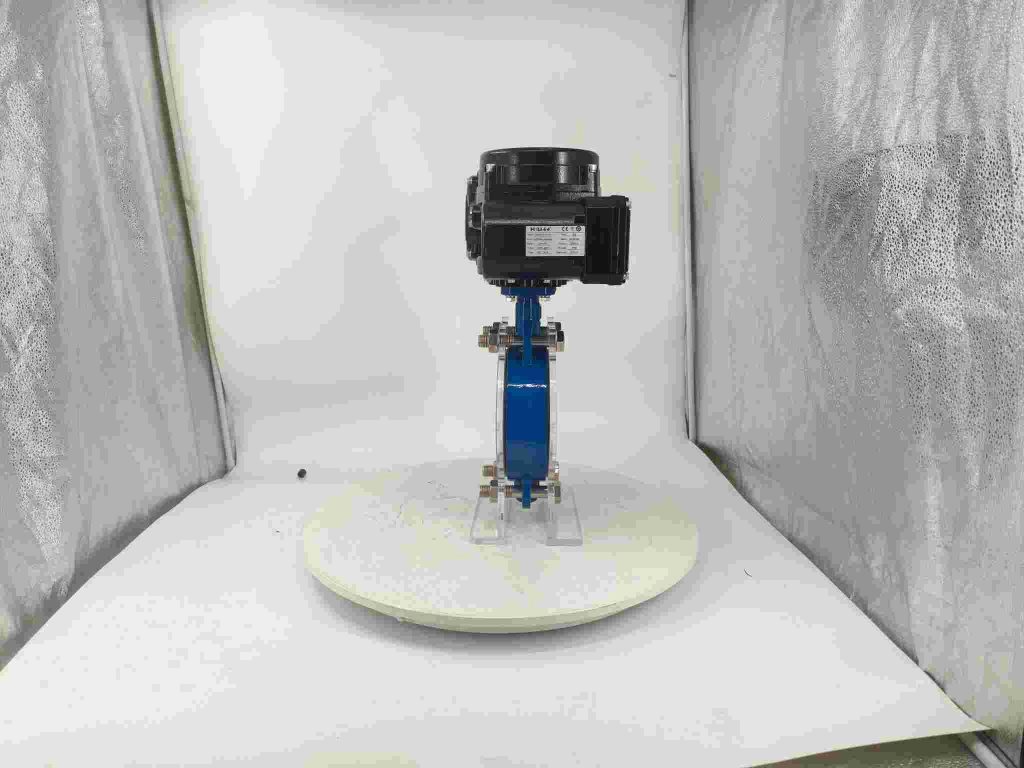

An explosion-proof electric butterfly valve is a type of valve that is specifically designed to prevent sparks or heat from escaping into the surrounding environment, which could potentially ignite flammable gases or vapors. These valves combine the functionality of a butterfly valve with the safety features of explosion-proof electrical equipment. A butterfly valve typically consists of a disc (or “butterfly”) that rotates to control the flow of liquids or gases, but with an explosion-proof design, it ensures that no electrical components inside the valve can cause an explosion. These valves are often used in industrial applications that involve flammable or explosive materials. They are typically constructed with materials that can withstand high temperatures, pressure, and exposure to chemicals. The electric actuator in these valves is designed to operate without creating any potential ignition sources, such as sparks or arcs, which are common risks in explosive atmospheres.