Relay assembly plays a critical role in the functioning of numerous electronic systems. It is a process where various electronic components, such as relays, connectors, switches, and other devices, are assembled to create a functional unit that can effectively control and manage electrical circuits. This article explores the importance, application, and design considerations of relay assembly in modern electronics.

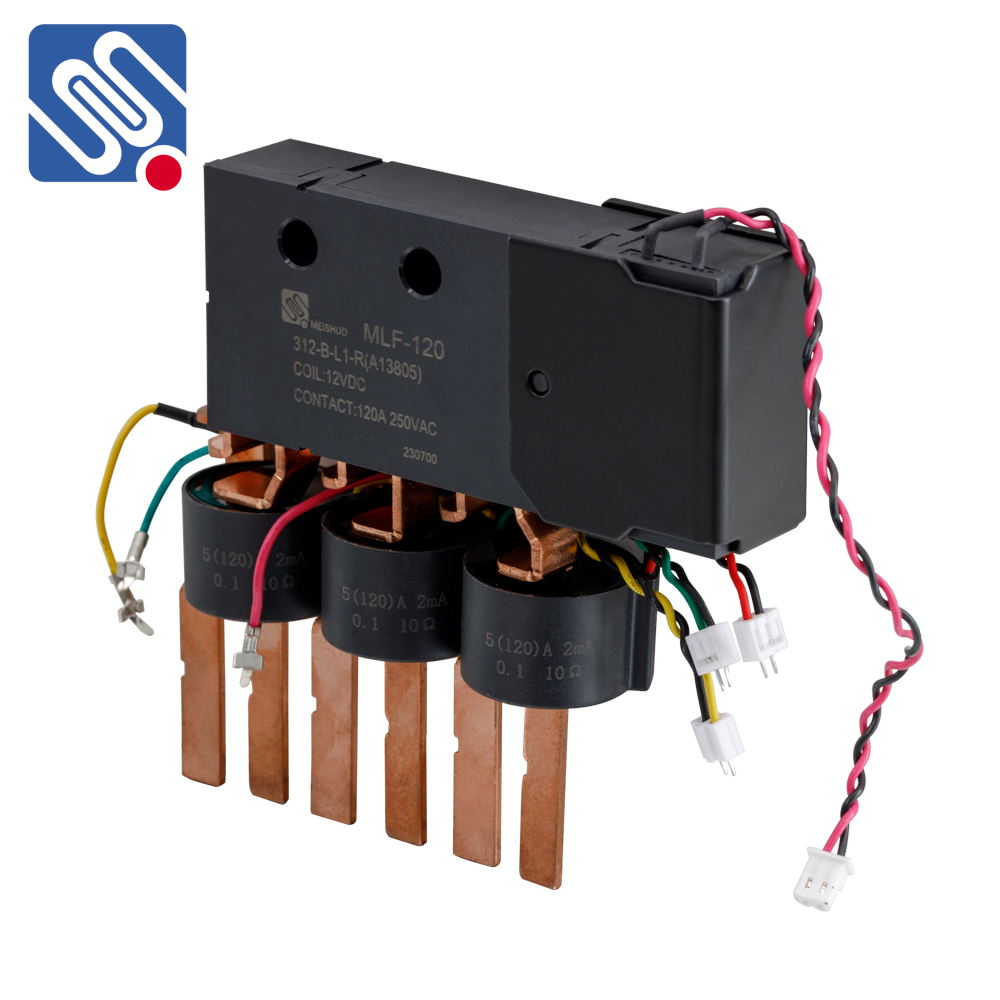

At its core, a relay is an electromechanical switch that allows a low-power signal to control a higher-power circuit. Essentially, it acts as an intermediary between a low-voltage control circuit and a high-voltage load, enabling safe and efficient operation. When a control signal is applied to the relay’s coil, it generates a magnetic field that closes or opens the switch contacts, allowing current to flow or stopping it. This functionality makes relays indispensable in various applications, including automation systems, industrial machinery, and automotive electronics. Relay assembly involves the careful integration of these relays with other components to form a complete assembly. This process can include wiring, soldering, and mechanical fastening, depending on the design specifications and application requirements. Typically, relay assemblies are mounted onto printed circuit boards (PCBs), where their connections are established to ensure reliability and efficiency in the circuit.