A Mini Solenoid Valve is a vital component in fluid control systems, offering an efficient, compact, and precise way to control the flow of liquids and gases. Despite its small size, this type of valve is designed to deliver high performance in various applications, ranging from industrial machinery to household appliances. In this article, we will explore the working principle, types, advantages, and applications of mini solenoid valves.

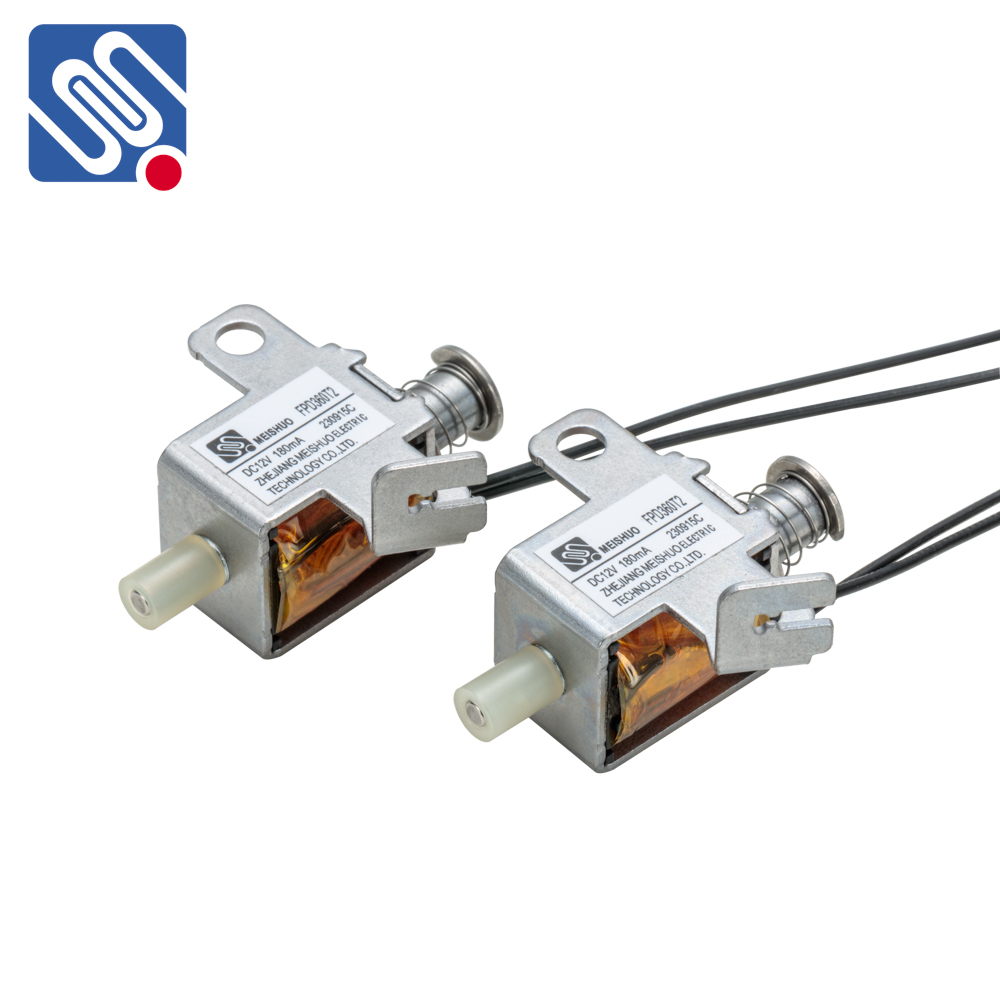

Working Principle of a Mini Solenoid Valve At its core, a mini solenoid valve operates based on electromagnetic principles. It consists of three main components: a solenoid coil, a valve body, and a valve plunger or core. The solenoid coil is energized when an electrical current flows through it, creating a magnetic field. This magnetic field then activates the valve plunger, causing it to move and either open or close the valve seat. When the valve opens, it allows fluid (liquid or gas) to flow through the valve body. Conversely, when the solenoid is de-energized, the spring mechanism returns the plunger to its original position, shutting off the flow of fluid. The fast response time and low energy consumption make mini solenoid valves a popular choice in applications requiring rapid on/off fluid control.