Solenoid valves are integral components in fluid control systems, offering precise regulation of the flow of liquids and gases. They are commonly used across various industries, including automation, water treatment, food processing, and chemical manufacturing. Among the different types of solenoid valves available, Stainless Steel and Plastic Solenoid Valves stand out due to their unique material properties, making them suitable for a wide range of applications. This article explores the features, applications, and benefits of these two types of solenoid valves.

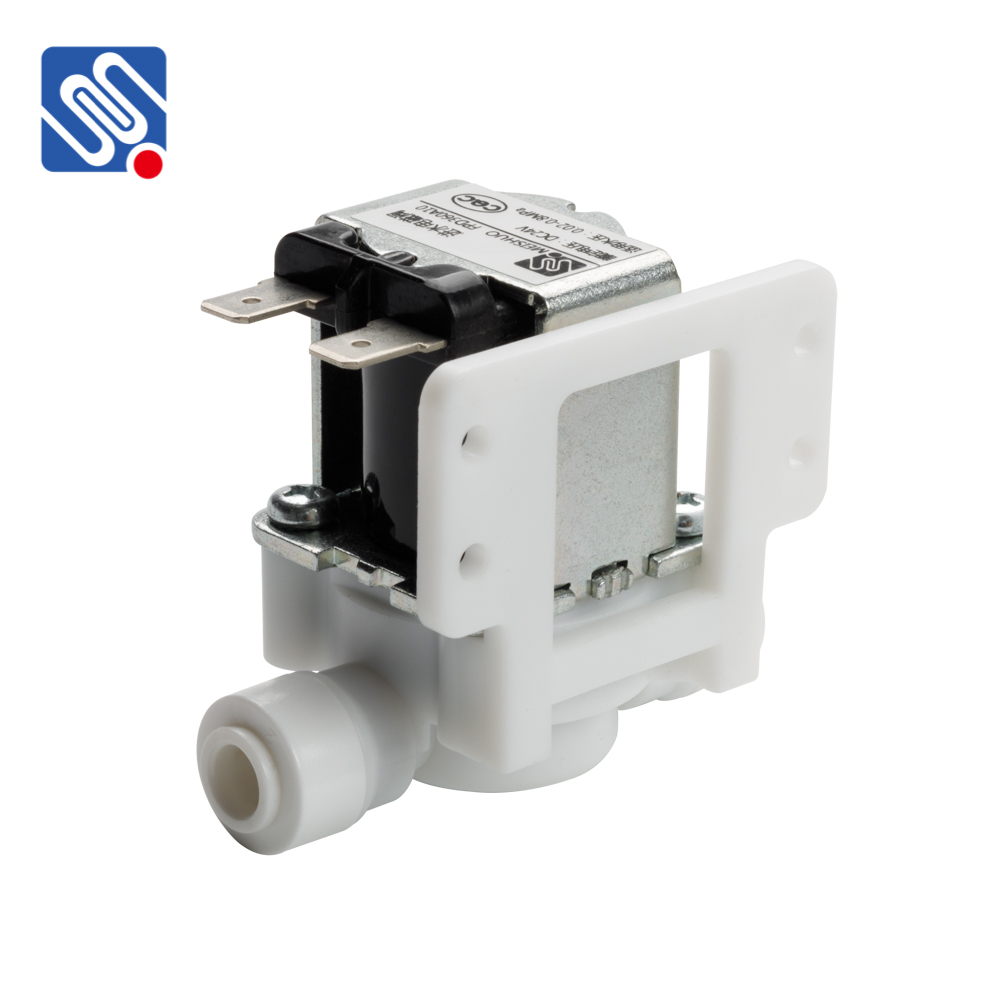

1. What Are Solenoid Valves? A solenoid valve is an electromechanical device that uses an electric current to control the flow of a fluid through a valve. The valve’s mechanism operates by a solenoid, which is an electromagnetic coil. When an electrical current is applied to the solenoid, it generates a magnetic field that moves a plunger or valve stem, opening or closing the valve. This simple yet efficient design makes solenoid valves ideal for automating fluid control in various processes. 2. Stainless Steel Solenoid Valves Stainless Steel Solenoid Valves are widely used in industries that require high durability, strength, and resistance to corrosion. These valves are typically constructed using high-quality stainless steel alloys such as 304, 316, or 316L, each offering different levels of resistance to various corrosive substances.

Leave a Reply

You must be logged in to post a comment.